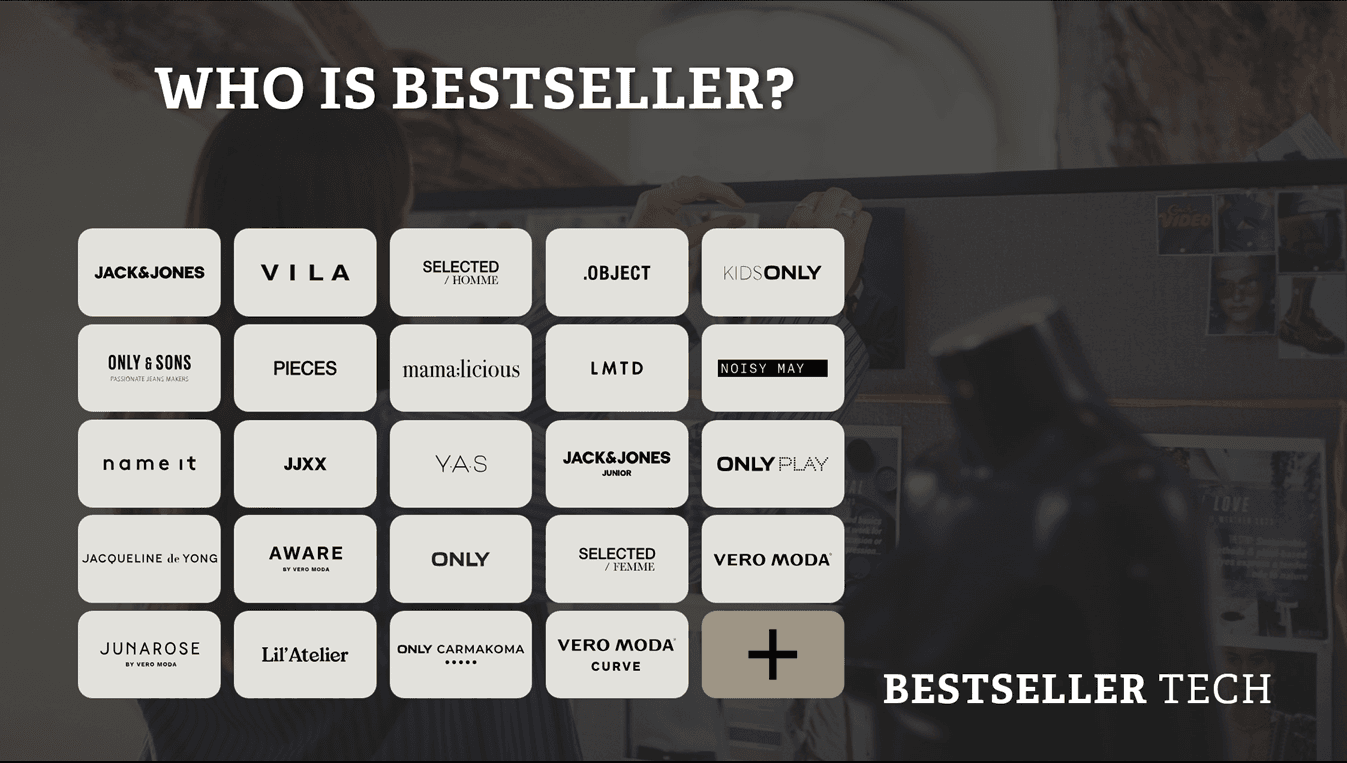

Founded in Denmark 50 years ago, BESTSELLER is an internationally family-owned fashion company with a strong foundation and more than twenty brands including JACK&JONES, ONLY and VERO MODA. There are approximately 2,800 branded BESTSELLER retail stores in 44 countries globally. The wholesale business sells products to more than 16,000 multi-brand and department stores globally. To orchestrate this network, BESTSELLER turned to the Manhattan Active Supply Chain Execution suite.

Its distribution network consists of five proprietary warehouses in Denmark, complemented by a network of regional logistics partners and a state-of-the-art automated distribution centre under construction in the Netherlands. This upcoming 155,000 m² facility built largely from FSC-sourced timber reflects the company’s commitment to design, innovation, and technology. Speed is as critical as accuracy. When a new collection arrives at a warehouse, the exact quantities for each store are already planned, leaving the warehouse to fulfil orders flawlessly and on time.

Future-proof supply chain

To keep pace with its growth, BESTSELLER needed a modern Warehouse Management System (WMS) capable of unifying processes across regions and accelerating global expansion. The answer was Manhattan Active Supply Chain Execution, a cloud-native replacement for the company’s legacy custom-built system. The platform ensures globally consistent warehouse and transportation processes for a truly unified supply chain and provides a powerful advantage: a fully integrated Warehouse Execution System (WES) to orchestrate advanced automation, including shuttles and robots. “We originally selected Manhattan’s warehouse management system in 2019, but the pandemic delayed implementation. Taking Manhattan’s advice, we transitioned to Manhattan Active Supply Chain Execution - a cloud-native, fully unified platform combining warehouse and transport management. It proved to be the right decision. Today, we benefit from quarterly automatic updates and the latest innovations”, says Svend Sørensen, Supply Chain TECH Product Owner at BESTSELLER.

“Processes now run as intended with the right orders picked, packed and shipped on time.”

Svend Sørensen, Supply Chain TECH Product Owner at BESTSELLER

Intelligent orchestration

The Manhattan Active WM is operational in three Danish warehouses, including the Taulov site, which uses an Exotec automated storage and retrieval system (AS/RS). Nearly 90 robots move bins of clothing and accessories to eight workstations, where operators pick and pack with speed and accuracy. The Manhattan application orchestrates these automated workflows alongside all the other warehouse processes, ensuring a seamless, high-performance operation. BESTSELLER will continue to roll out the Manhattan solution wherever operational control is required, including the new Lelystad warehouse in the Netherlands. This site will feature Europe’s largest shuttle system, designed to house 1.4 million bins and 1,400 robots. Sørensen: “Integrating with advanced AS/RS systems made this one of our most complex projects. Manhattan’s consultants were instrumental, always listening, providing honest feedback, and offering smarter alternatives when ideas weren’t feasible. That partnership was key to our success.”

Cost efficiency

Migrating from legacy systems to the Manhattan Active Platform marked a significant transformation for BESTSELLER, and a substantial change for their warehouse teams. Initial adjustment soon gave way to improved performance with operators now working faster, more accurately and efficiently than ever. Following go-live, BESTSELLER achieved a significant reduction in cost per order line and improved visibility across the supply chain. Every box can now be tracked from warehouse receipt to store delivery, enhancing overall operational quality and control. “The biggest gain is quality. Processes now run as intended with the right orders picked, packed and shipped on time. When we leverage the Manhattan Supply Chain Execution suite fully, productivity gains and cost reductions follow naturally.” This is only the beginning, Sørensen emphasizes: “We’re exploring Yard Management, Appointment Scheduling, Labour Management, and the exciting potential of AI. Manhattan’s innovation roadmap promises to make life even easier for our teams.”

“A single solution simplifies planning and ensures shipments are ready when carries arrive.”

Svend Sørensen, Supply Chain TECH Product Owner at BESTSELLER

A unified supply chain

With warehouse management optimised, BESTSELLER is extending the platform to transportation management. This unified approach allows seamless coordination from planning to fulfilment, reducing friction, improving responsiveness, and lowering costs. After optimising outbound flows, inbound processes are next, with Manhattan as a long-term innovation partner. Sørensen: “Unifying warehouse and transportation management brings tremendous benefits. We serve many customers with different needs, transport modes, and schedules. A single solution simplifies planning and ensures shipments are ready the moment carriers arrive. With Manhattan, we’re unlocking even more potential in our supply chain.”

![]()

Download the case study

Download the case study

Wilt u een fysiek exemplaar van het magazine ontvangen? Stuur een mail naar ce@manh.com o.v.v. Commerce Trends 2025, en vermeld bedrijfsnaam, uw naam, adres en woonplaats. Wij sturen u dan een exemplaar toe.

Reacties 0